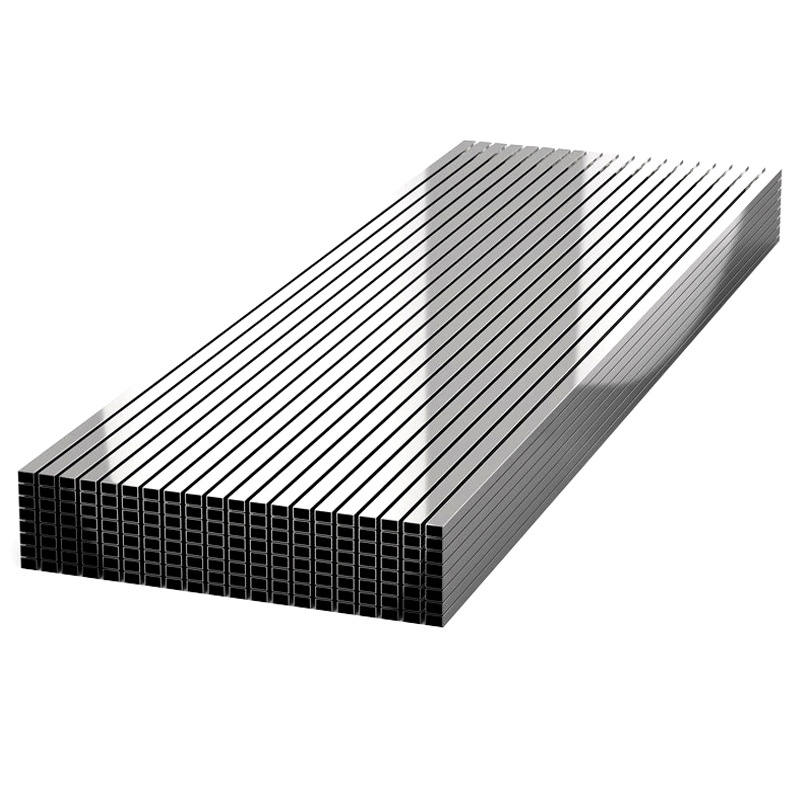

| Name: | Galvanized steel square/ rectangular pipe |

| Product name: | Galvanized steel square/ rectangular pipe |

| Technique: | Hot rolled / cold rolled |

| Wall thickness: | 1mm~20mm |

| Outer Diameter: | 21.3MM~1620MM |

| Surface Treatment: | 1. Galvanized 2. Black 3. Transparent oil,anti-rust oil |

| MOQ: | 25tons.We also can accept sample order. |

| Certificate: | ISO901, CE |

| Applications: | Make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight. |

| Price terms: | FOB, EXW, CIF, CFR |

| Payment terms: | 30% T/T as deposit + 70% balance before shippement |

| Inquiry |

Product Description

A galvanized steel square tube is a hollow, square-shaped metal tube made from galvanized steel. The galvanization process involves coating the steel with a layer of zinc to protect it from corrosion and rust. This type of steel tubing is widely used in various applications due to its durability, corrosion resistance, and versatility. Here are some key features and uses of galvanized steel square tubes:

Corrosion Resistance: Galvanizing the steel square tube adds a protective layer of zinc, making it highly resistant to corrosion. This is particularly important for outdoor applications where exposure to the elements could lead to rust and deterioration.

Strength and Durability: Galvanized steel is known for its strength and durability, making it suitable for structural applications. The square shape of the tubing provides additional rigidity and stability.

Versatility: Galvanized steel square tubes come in a range of sizes and thicknesses, offering versatility for various construction and manufacturing purposes. They can be used in a wide array of applications, including frames, support structures, fencing, and general construction.

Ease of Fabrication: The square shape makes these tubes relatively easy to work with in terms of cutting, welding, and shaping. This ease of fabrication contributes to their popularity in construction projects.

Cost-Effective: Galvanized steel square tubes are often considered cost-effective due to their long lifespan, low maintenance requirements, and resistance to corrosion. The initial investment in galvanized steel can be offset by the reduced need for repairs or replacements.

Wide Range of Applications:

Construction: Used in the construction of frames, support structures, and building components.

Fencing: Commonly used for the construction of fences and gates.

Engineering Projects: Suitable for various engineering applications where a combination of strength and corrosion resistance is required.

Manufacturing: Utilized in the fabrication of machinery, equipment frames, and other industrial applications.

Recyclability: Galvanized steel is recyclable, contributing to its sustainability and environmentally friendly profile.

Send Email

Send Email +86-17691203929

+86-17691203929